Purpose of the flight and payload description

The purpose of the high altitude solar cell calibration program was to produce air mass zero (AM0) standard solar cells that could be used for accurately setting solar simulator intensities. The program was started in 1962 by the Jet Propulsion Laboratory, of the California Institute of Technology in Pasadena.

Since the output of solar cells is spectrally selective, the electrical power derived from solar cells depends on the total intensity and the spectral distribution of the light source: the Sun. Attempts were made to procure a laboratory light source which has the same spectral character and intensity as the Sun. However, such attempts have been complicated as different types of radiation sensing devices, such as pyrheliometers and thermopiles, have been used which can not be accurately calibrated on either a total intensity or spectral intensity basis. To overcome this was introduced the concept of flying cells on a balloon, to measure their output at altitudes, to recover the cells and to use them as reference standards. The calibrated standard solar cell is placed in the solar simulator beam, and the beam intensity is adjusted until the standard solar cell reads the same as it reads on the balloon.

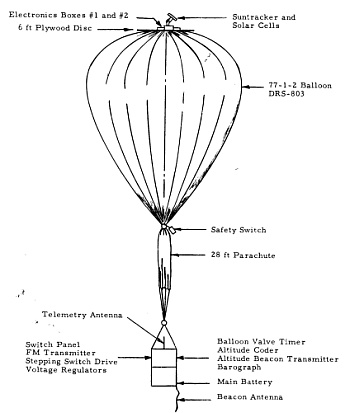

Althought, some modifications were introduced over time, the main components of the balloon flight system were maintained along the entire program: a sun tracker, a helium-filled balloon, a telemetry system, and a battery power supply, as shown in the scheme at left (click for more detail). The sun tracker was mounted on the balloon apex, which is the most stable position of the balloon system. The telemetry transmitter and battery power supply, along with several instruments for measuring altitude, were suspended in a second gondola beneath the balloon. An electrical cable, incorporated into the balloon during manufacture, connected the top and bottom payloads.

The solar tracker was used to position the solar cell payload toward the sun, independent of balloon movements. The tracker was capable of movement in both elevation and azimuth to maintain an "on-sun" condition within +2 deg. A reflection shield attached to the solar tracker was used to prevent unwanted reflected light from reaching the solar cell payload. The tracker and associated electronics boxes were mounted on a plywood disk 6 ft in diameter, which, in turn, was bolted to the balloon top end fitting. The plywood disk permited the tracker to "float" on top of the helium bubble. Total weight of the upper payload was approximately 23 kg.

Details of the balloon flight

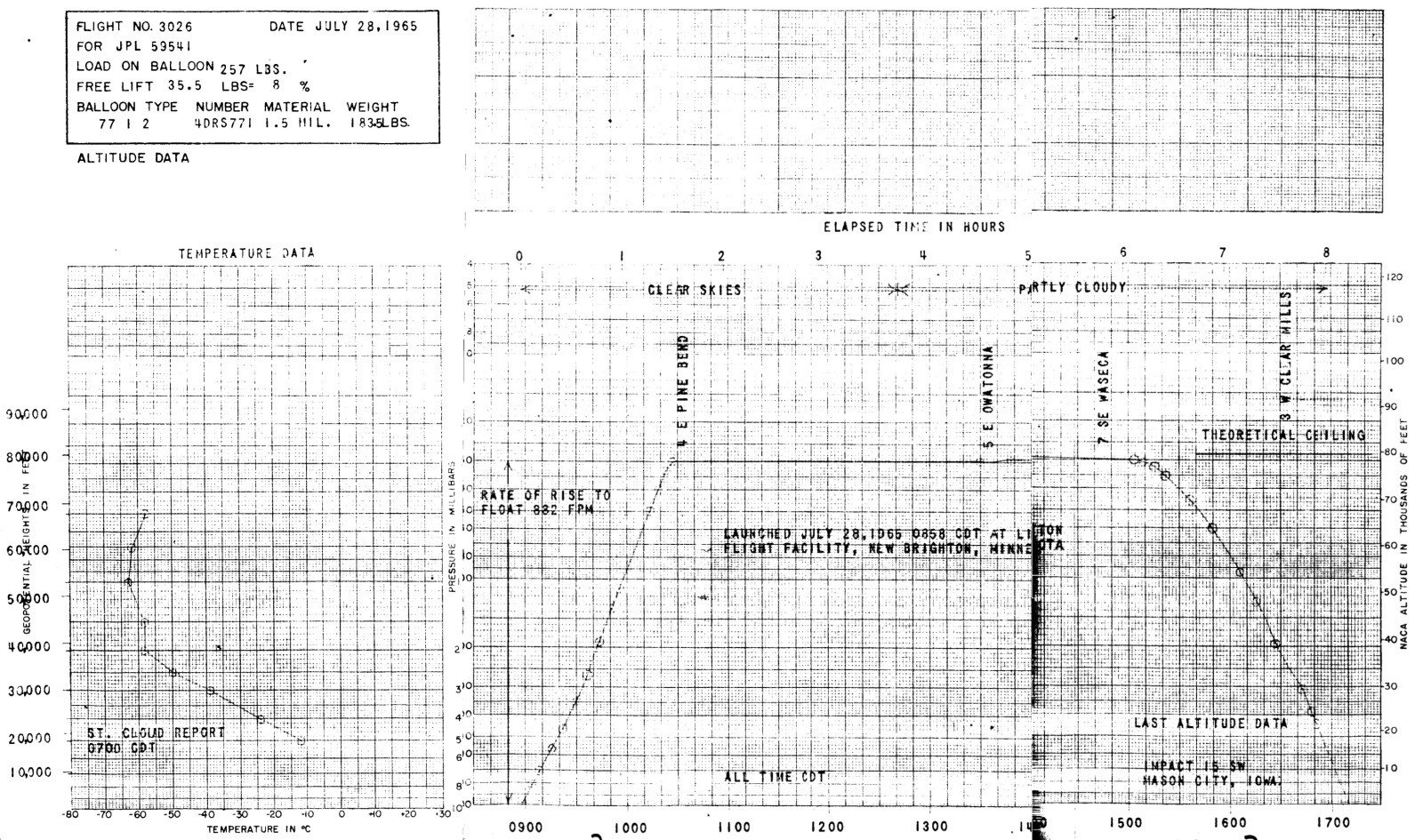

Balloon launched on: 7/28/1965 at 8:58 cdt

Launch site: University of Minnesota Airport, New Brighton, US

Balloon launched by: Litton Industries Inc.

Balloon manufacturer/size/composition: Zero Pressure Balloon 77-1-2 4DRS771 (1.5 mil)

Flight identification number: LITTON 3026

End of flight (L for landing time, W for last contact, otherwise termination time): 7/28/1965 at 17:10 cdt

Balloon flight duration (F: time at float only, otherwise total flight time in d:days / h:hours or m:minutes - ): 8 h 12 m

Landing site: 15 Miles SW of Mason City, Iowa, US

Payload weight: 257 lbs

The balloon was launched by dynamic method from the Litton Flight Facility located near New Brighton, Minnesota at 8:58 CDT on 28 July 1965 as Flight No. 3026. The balloon took a S-SE course during ascent to a point over Pine Island, Minnesota. During the four and one-half hour float period, the direction was SW to a position ten miles south of Waseca, Minnesota. During descent the balloon system moved southeast to an impact point 15 miles southwest of Mason City, Iowa. Direct line distance from the launch site to the impact point was 145 miles due south, the lower payload touched down in a field of tall corn; the impact switch actuated the rip panel, but the lower payload was dragged about 200 yards by surface winds until the balloon was sufficiently deflated to lay over into the corn. System damage was minor; the tracker had a sheared drive pin and a quantity of battery acid had spilled. The corn field was damaged, but no special recovery problems were encountered and the system was returned to the Litton plant the following morning.

External references

- Suntracker Balloon Flights - Flights 3026, 3028, 3029 and 3031 Technical Report - Litton Systems, Inc., 1965

If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.