Purpose of the flight and payload description

This flight was part of an air sampling program started at the Institute of Space and Astronautical Science (ISAS) of Japan by a group led by Prof. T. Itoh in 1978. The objective of the program was to obtain stratospheric and tropospheric air samples above Japan first using a balloon-borne grab sampler and later a cryogenic sampler. After each flight those samples were distributed among collaborating scientists whom analyzed minor constituents of the stratospheric air using precise analyzers in their laboratories.

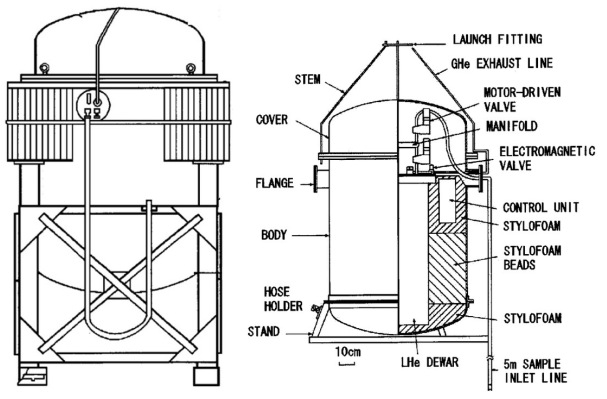

A schematic diagram of the cryogenic sampler is shown at left (click to enlarge). It consisted mainly of 12 stainless-steel-sample containers, a liquid helium dewar, a receiver, a transmitter, a control unit and batteries; all these components were housed in an aluminum chamber pressurized at 1 x 105 Pa. The volume of each sample container was about 760 ml and the inner wall of each container was electrically polished. A motor-driven metal-to-metal seal valve was attached to each sample container. The other end of the motor-driven valve was connected to the sample intake through a manifold. Air samples were introduced into the containers through a 5 m bellows tube, of which one end was located 4 m below the bottom of the sampler to avoid possible contamination from it.

All parts were made of stainless steel and connected to each other with metal gaskets. After assembly, the leakage of the system was confirmed to be minimal by a mass spectrometer leak detector, and all tubing including the sample containers were evacuated for longer than one month to make their insides clean. Prior to air sampling, a similar evacuation was made for about one

week, and then the valves were closed and the sample containers were cooled to -269º C by filling the dewar with liquid helium. Total weight of the sampler was about 260 kg.

To minimize contamination from the balloon, the sampler was suspended about 120 meters below the balloon by a stainless steel wire and air samples were collected at assigned heights during the descent of the balloon. The maximum height of air samples collected ranged from 25.0 to 35.0 km, depending on the size of the balloon used. At each assigned height, the motor-driven valves were opened and closed using a telecommand. The amount of air samples collected was approximately 25 liters. To avoid intrusion of contaminated surface air into the sample containers, the stainless-steel bellows tube was also evacuated together with the containers and its evacuation was broken when the balloon ascended to the maximum height.

Once the balloon flight was completed the sampler detached from the balloon and descended under his own parachute. The sampler was recovered within an hour of the impact in the sea surface. Back in the laboratory, the sample containers were laid for about one month to ensure that respective components ofthe air samples were mixed well in the containers before proceeding to analyze them.

The two flights carried out in 1997 in ESRANGE as part of the ILAS validation campaign marked the first time the cryogenic sampler was meant to land on ground (until then, in all the previous flights the apparatus was recovered from the ocean). For that purpose the sampler was fitted to a specially built gondola (which can be seen in the left image) made of aluminium that served to protect it from the hard conditions of landing. Also the operation of the device was adapted to reduce the flight time by programming the sampling process also during balloon ascent.

Details of the balloon flight

Balloon launched on: 2/22/1997 at 9:03 utc

Launch site: European Space Range, Kiruna, Sweden

Balloon launched by: Centre National d'Etudes Spatiales (CNES)

Balloon manufacturer/size/composition: Zero Pressure Balloon model 100z 100.000 m3

Balloon serial number: 100Z Nº 95

End of flight (L for landing time, W for last contact, otherwise termination time): 2/22/1997 at ~ 12:10 utc

Balloon flight duration (F: time at float only, otherwise total flight time in d:days / h:hours or m:minutes - ): 3 h 7 m

Landing site: In Finland

Campaign: ILAS VALIDATION 97

Payload weight: 746 kgs

Gondola weight: 317 kgs

External references

- Calibration and quality assessment of DESCARTES: grabsampler for stratospheric tracers Doctoral thesis by Arvelius, Johan, Umeå University, Faculty of Science and Technology, Space Science (2005

- Cryogenic Air Sampling Group homepage Tohoku University website

- List of balloons launched from ESRANGE SSC Space website (via Archive.Org)

- Research on Balloon-borne Whole Air Sampling System for Studying Stratospheric Minor Constituents Thesis by Hideyuki Honda -In Japanese- (2001)

- Variations of stratospheric trace gases measured using a balloon-borne cryogenic sampler Advances in Space Research, Vol 30, Issue 5, 2002, Pag 1349

If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.