Purpose of the flight and payload description

The Sky Anchor System was a two balloon system developed and tested by the National Scientific Balloon Facility (NSBF), during the 70's and 80's decade as part of a long lasting effort of the agency to develope a long duration balloon system. The concept -originally tested in a small scale in 1963- was boosted by the needs of the scientific ballooning community which could benefit in many areas of interest from longer exposure times at altitude. The final goal of the developmental effort was to built a vehicle capable of transport a 500 lb scientific payload at 130,000 ft for a minimum of 100 days duration.

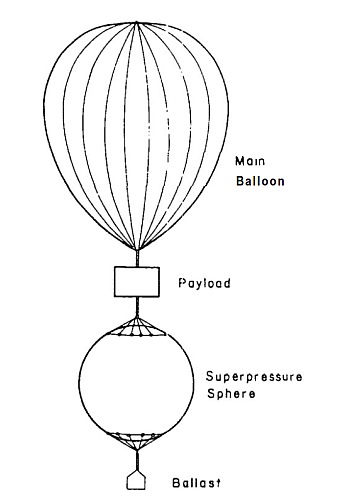

The Sky Anchor system used a two balloon system on which a conventional zero pressure balloon (open) carried below a super pressure balloon (closed) which acted as ballast and anchor. In the image at left is a basic scheme of the system (a more detailed description can be seen clicking over the drawing).

The theoretical operation of the system was as follows. Once the system was airborne, on the way to the main balloon's operational altitude, the super pressure became filled and pressurized. As the "super pressure" continued to be carried upward it losed more and more lift. When sunset occured the entire system descended to a new equilibrium altitude where the increase in lift on the super pressure balloon just equaled the sunset effect on the main balloon. Although its volume was decreased, no gas was lost from the main balloon. At sunrise, the main balloon expanded and the system once again rose. In so doing the super pressure balloon losed the lift that it gained at sunset and the system stabilized at the same altitude as the preceding day. Since there was no change in suspended weight on the main balloon, it should not overshoot and again there will be no loss of gas. As in the pure super pressure system, assuming there were no leaks, the flight duration was limited only by creep, gas diffusion and ultraviolet degradation of the balloon fabric.

Throughout the development of the program, the actual flight experience turned out to be much more complex than planned, so after mixed results on 14 flights over six years, the program was abandoned in 1982. However, the experience gained would pave the way for other groups to develop more successful designs in the future. This would allow the original goal behind Sky Anchor to be achieved in the early decades of the 21st century.

Details of the balloon flight

Balloon launched on: 9/9/1981 at

Launch site: Donaldson Center, Greenville, South Carolina, US

Balloon launched by: National Scientific Balloon Facility (NSBF)

Balloon manufacturer/size/composition: Zero Pressure Balloon Winzen - 218.040 m3 (12.70 microns) - Raven 56.634 m3 (50.80 Microns polyester)

Balloon serial number: 266.82-0.5-NSCR-0.8 Cap SN:1

Flight identification number: 178N

End of flight (L for landing time, W for last contact, otherwise termination time): 9/11/1981

Balloon flight duration (F: time at float only, otherwise total flight time in d:days / h:hours or m:minutes - ): F 45 h

Payload weight: 544 kgs

Sky Anchor XIII was the thirtheenth test flight of the system and the first one carrying succesfuly a 1200 lb payload, twice the weight from previous flights. The balloon system consisted of a 7.700.000 cubic feet zero pressure balloon, and a 2.000.000 cubic feet super pressure anchor balloon constructed of 0.92 x 0.92 mil material. The flight, was launched from Greenville, South Carolina on September 9 1981 and lasted lasted 45 hours. All equipment on-board performed well with the exception of ARGOS. Data were received on 17 ARGOS passes but only 3 positions were computed.

The Interim Long Duration Electronics Platform (ILDEP) provided near real time (35 min delay) data through the GOES system and the NSBF PDP11/34 engineering computer. Data, available through dial-upup phone link, was reduced to engineering units and displayed at NSBF but far from being automated, it required a considerable amount of operator interaction.

External references

- National Scientific Balloon Facility Annual Report FY 1981 National Center for Atmospheric Research, April 1982

- Study and Analyze Energetic Particle and Magnetic Activity Data Final rept. 1 Apr 79-31 Mar 82

If you consider this website interesting or useful, you can help me to keep it up and running with a small donation to cover the operational costs. Just the equivalent of the price of a cup of coffee helps a lot.